Hyundai Mipo Dockyard (HMD) announced Tuesday that it is on schedule to deliver the first ballast free liquified natural gas (LNG) bunker vessel to Germany-based Bernhard Schulte Ship by the end of 2018.

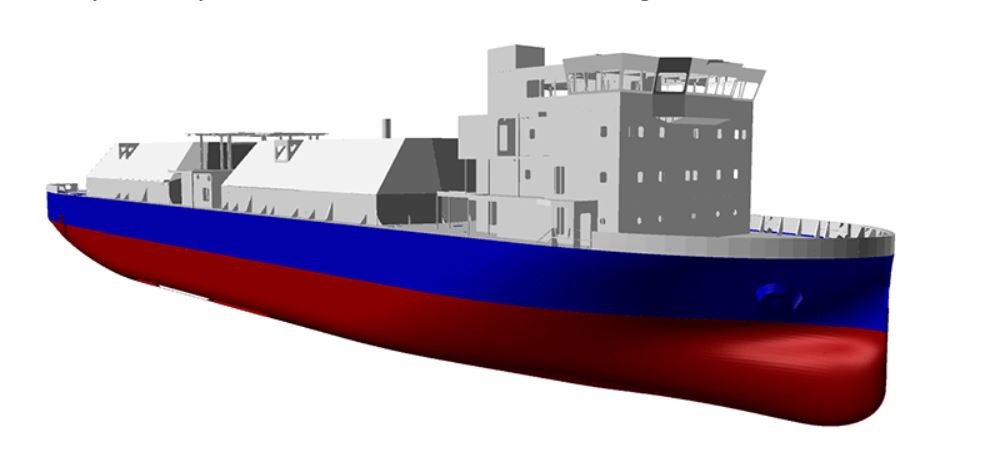

The 7,600-cubic meter vessel is under construction at the HMD shipyard in Ulsan, South Korea. The design utilizes a specialized hull form with dead-rise, a forward-positioned engine room and deckhouse, and a twin propulsion system to maintain damage stability and trim and heel control without ballasting, the company said.

“We are delighted to work with the shipyard helping the marine industry bring innovative designs to the market,” Jin-Tae Lee, a chief representative and marine manager at the Ulsan shipyard, said. “We believe that this design is another remarkable development for HMD to realize the industry’s need for safe, efficient and clean requirements in the shipping industry worldwide.”

The ballast-free design means that the bunker vessel won’t have to comply with IMO requirements that new ships be delivered with ballast water treatment systems to reduce the ecological, environmental and health threats of steel-hulled vessels that use ballast water.

“The ballast-free concept will be made a reality by the technology expertise of HMD,” Seung-Ho Jeon, the senior vice president of initial planning at HMD, said. “We aim to stand out in the field of eco-friendly business practice.”

To overcome speed management challenges arising from dead-rise, HMD developed a specialized hull form that has held up in wet model tests. The twin propulsion system is another key piece of the ballast-free design, with the small design of its two azimuth thrusters able to be fully immersed in all conditions.

The vessel will be equipped two independent C tanks that can store LNG at a minimum temperature of minus 165 degrees celcius and maximum vapor pressure of 3.75 bar(g).