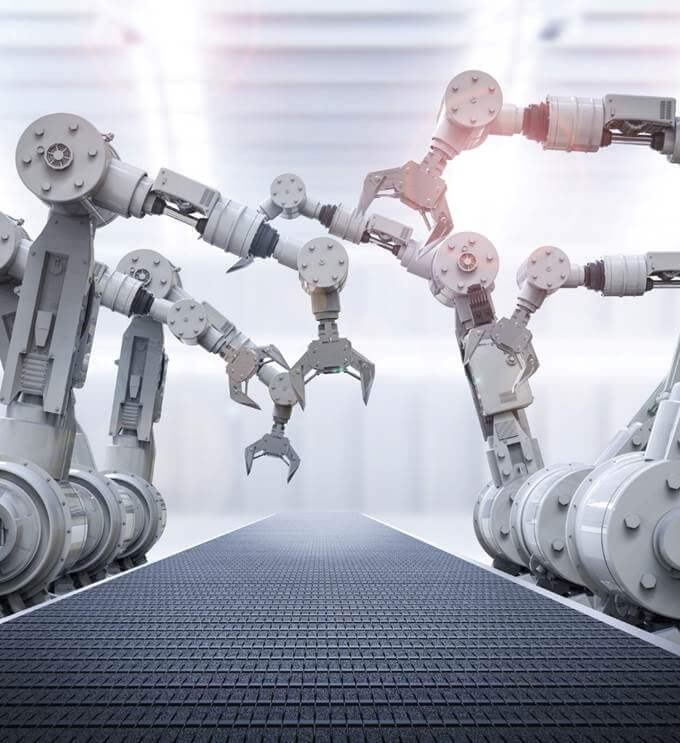

On Tuesday, AAA20Group, LLC, a robotic solutions provider, announced the integration of their Collaborative Palletizer Robot with an automatic stretch wrapper to provide a labor-saving end-of-line packaging solution.

The cooperative machine integration combines to packaging solutions, the company said, that combines the robotic component features of a CP-100 or CP-200 robot capable of gripping between 22 and 44 pounds with an automatic stretch wrapper machine to create a single packaging operation. The integration offers significant cost-benefit advantages, the company said and replaces the need for one to two human workers, while reducing the risk of pallet failure during internal transportation, increasing efficiency and cost savings.

“Our innovative integration effectively addresses the common issue of transporting loose pallets that are not properly secured or wrapped,” said Karen Mallouk, co-founder of AAA20 Group. “This can result in products shifting or falling off during transportation, causing potential damage or loss. For example, unstable stacks of diapers or feminine care products can fall during the short journey from the palletizer to the stretch-wrapper machine. With our solution, this problem is eliminated as the stacking and wrapping processes are seamlessly combined in one location.”

The solution also eliminates the need for robotics or stretch wrapper machinery expertise, the company said, by providing a turn-key solution to shippers.

“We will match the robot/shrink wrapper combination with your specific application,” Mallouk said. Choosing “the ‘robot-as-employee’” subscription level can provide companies with the ability to reallocate workers to higher-level activities, optimizing human capital.